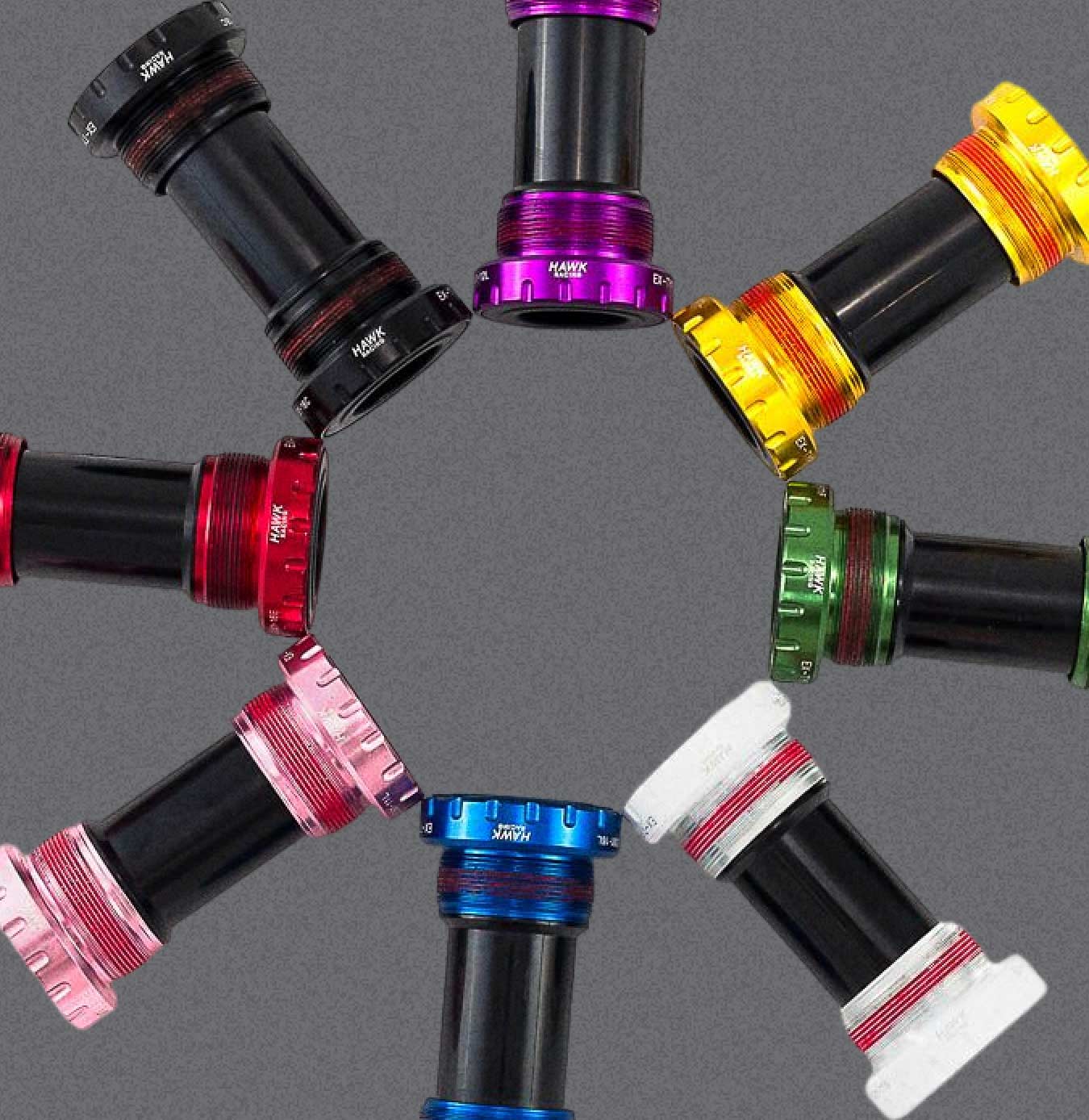

Find Your

New Bottom

Bracket

Whether you prefer the road, the trail, or anything

in between, Hawk Racing has the perfect bottom

bracket to fit your bike.

- Bottom Brackets

- BB86/92

- $129.00 – $175.00

- Select

- Bottom Brackets

- ENG Threaded Bottom Bracket

- $129.00 – $176.00

- Select

You love our bottom brackets, now you

can have the same technology that leads

the industry in your wheels.

Zeus Has Arrived

Derailleur Pulleys

Experience the industry leading

alloy derailleur pulley wheels that

are changing the game forever.

alloy derailleur pulley wheels that

are changing the game forever.

SRAM pulley set

Shimano Pulley set

Get the Facts!

Check out the Friction Facts independent bottom

bracket study that put us on the map. Get the facts

on how our competitors really stack up.

bracket study that put us on the map. Get the facts

on how our competitors really stack up.

Locate a Dealer Near You

Use our Dealer Finder for an Authorized

Hawk Racing Dealer near you.